Electroplating vs Solid Brass

A quick insight into the electroplating process and what we've learnt.

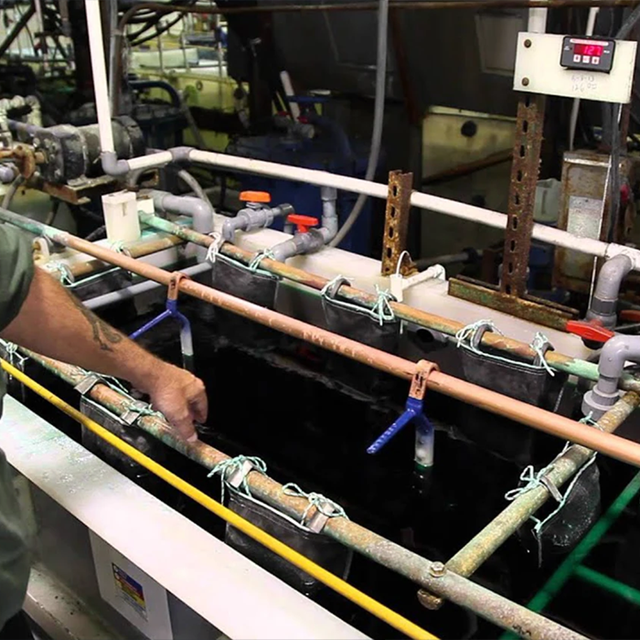

What is Electroplating?

Electroplating uses an electrical current to apply a thin layer of metal to the surface of another metal. Common electroplated finishes include brass, copper & chrome.

Why?

The main 2 reasons are to stop corrosion or for the aesthetic look of the metal.

These factors have a lot to do with the preparation of the base material.

- If the item is large & difficult to handle, if it has wide flat surfaces and/or is made of thin sheet metal.

- It has an irregular shape with many hard to reach places and/or sharp corners.

- The result is meant to be a highly polished.

Clear coat on electroplating

This is because if left un-coated it will need to be polished, eventually resulting in the removal of the plating.

Why we prefer to use solid material like brass.

At Arkivio we prefer not to electroplate and choose to use solid metals like brass or stainless steel.

- You do not need to clear coat a solid material, instead you can let it age and polish as needed. The metal will gain its own character and find beauty in its patina.

- There is no risk of the plating coming off, because it is solid.

- We are completely in control of the process, with plating the object must be finished in our factory and sent off to the electroplaters. The result may not always be up to our standards.

Some of our solid brass items are listed below: